such as Prosper, Pipesim, or IHS Harmony (some comparisons here). Finally, measured wellhead pressure and gas flow rate were used to calculate and compare bottom-hole pressure from correlations of pipesim and after-before. In black oil mode, a large number of correlations are available that can be. According to the current circumstances of the wells, the depth optimized for injection is the maximum allowable depth of injection which is deeper than the packer by 100 ft and the amount of injection gas is (1.5, 1, 1, and 1) MMscf/day for wells (AD2-11-2H, AD2-15-2H, AD4-13-3H, and AD4-19-2H) sequentially and injection pressure (2050, 2050, 2050, and 2000) psi for wells (AD2-11-2H, AD2-15-2H, AD4-13-3H, and AD4-19-2H) sequentially. Package for computing pressure profiles for gas lift optimization of oil & gas wells. The first point is how the flow regimes are incorporated into the flow correlations.

#Gas lift pipesim correlations software#

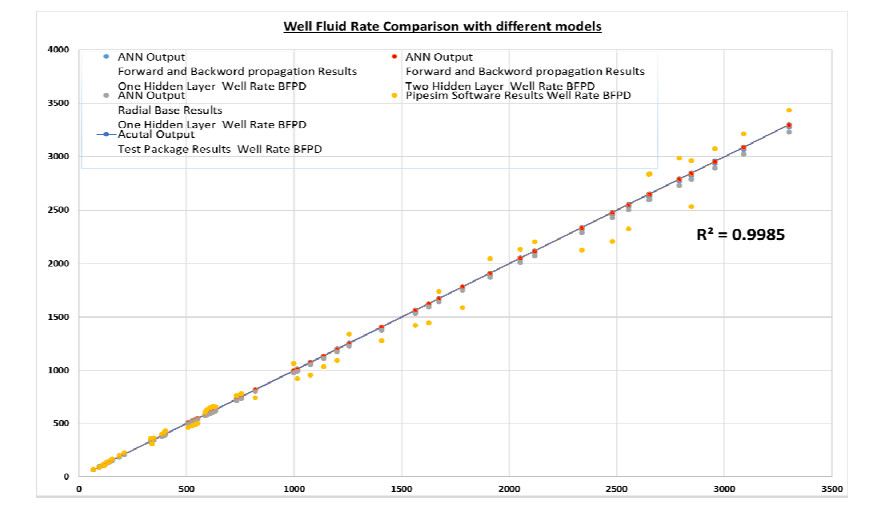

The use of PIPESIM software include determining artificial lift performance to determine the optimum amount of gas injected, optimum injection pressure as well as the optimum injection depth and knowing the impact of these factors on production, as well as the determination of the optimal injection conditions when water cut changes. The example flow regime maps shown in Figure 6.11 and Figure 6.12 illustrate two important points. According to the statistical results, Mukherjee & Brill correlation is the best option for all wells. Engineering analysis for gas and gas condensate reservoirs selecting the optimal production method. The work in this study includes using PIPSIM software to build a model of four studied productive wells (AD1-11-2H, AD2-15-2H, AD4-13-3H, A4-19-1H) after choosing the suited correlation for each well. PIPESIM Course, Information on Flow Correlations used within PIPESIM, (1997). This study suggests exploitation of gas associated with oil production to be recycled to lift oil as a substitute for the ESP. the gas-lift line by including the gas-lift line as a separate branch to. In addition to that, electrical submersible pumps (ESP) were used in some productive wells. Therefore, many water injection wells were drilled by the operators to maintain the reservoir pressure during production. This makes it difficult to produce economic oil rates. All the equations presented are solved using the Pipesim software, whose use is widely spread in artificial lift engineering as well as in pipeline. University of Baghdad, College of EngineeringĪhdeb is one of the Iraqi oil fields, its crude characterized by medium API (22.5-28.9) and highly reservoir pressure depletion from Khasib formation due to lack of water drive. Wells Network modeling for gas lift optimization and bottlenecking determination using PIPESIM Working on a Well X Well review project for SonaTrach Company Algeria as a part of a team responsible for optimizing and enhancing performance of wells (Natural and artificially lifted) equipped with slotted liner, cemented and perforated liners.

Together with the OLGA dynamic multiphase flow simulator, Schlumberger provides a complete software solution for designing and optimizing production systems.

10.Petroleum research and development center PIPESIM Version 2018.1 Release Notes 2 Schlumberger-Private Overview PIPESIM is Schlumberger’s flagship well and network modeling software for steady-state multiphase flow simulation.Well Performance analysis Pipeline and Facilities Network analysis Petroleum Production Engineering Member of Iranian Petroleum Institute (IPI) Member of University researchers and elite club Member of Society of Petroleum Engineer (SPE) This study suggests exploitation of gas associated with oil production to be recycled to lift oil as a substitute for the ESP.

0 kommentar(er)

0 kommentar(er)